Gathering Your Supplies

Embarking on the journey of making your own diecast cars is a rewarding hobby that combines craftsmanship with a love for automobiles. Before you begin, the first step is to gather all the necessary supplies. This initial preparation is crucial, as having everything at your fingertips will streamline the process and make it more enjoyable. Ensuring you have the correct tools and materials will save you time and frustration, allowing you to focus on the creative aspects of building your miniature masterpiece. Consider this stage as the foundation upon which your diecast dreams will be built. From selecting the perfect car body to choosing the right paints and decals, the choices you make now will influence the final appearance of your diecast creation. Take your time to research and select quality materials, as this will significantly impact the outcome of your project. Preparing well will set you up for success.

Essential Tools You’ll Need

To successfully make diecast cars, you will require a variety of tools. These tools are the instruments of your craft, enabling you to shape, assemble, and detail your miniature vehicles. A precision hobby knife is essential for trimming parts, removing flash, and making intricate cuts. A set of small screwdrivers will be invaluable for disassembling and reassembling the car, as well as for attaching various components. Fine-tipped paintbrushes in various sizes are crucial for applying paint, detailing, and adding fine lines. Tweezers will help you handle small parts, such as decals and interior details, with ease. A cutting mat protects your work surface and provides a stable base for cutting and assembly. A well-lit workspace is also key. Consider investing in a magnifying lamp to enhance visibility, especially when working on small details. These tools are the minimum you’ll need.

Materials for Diecast Cars

Beyond tools, the materials you choose will define the look and feel of your diecast cars. A diecast car body, often pre-made from metal or plastic, forms the foundation of your project. High-quality paints, specially formulated for model cars, are available in various colors and finishes, allowing for customization. Decals and stickers add intricate details, replicating authentic car designs or creating unique custom looks. Adhesives, such as super glue and model cement, are vital for assembling the various parts of the car. Thinners and solvents are used for cleaning and thinning paints. Sandpaper and polishing compounds will help you achieve a smooth, professional finish. Additional materials include clear coat for protection, masking tape for precise paint lines, and putty for filling imperfections. Consider what you want to achieve before starting, and source your materials in advance.

Preparing the Diecast Car Body

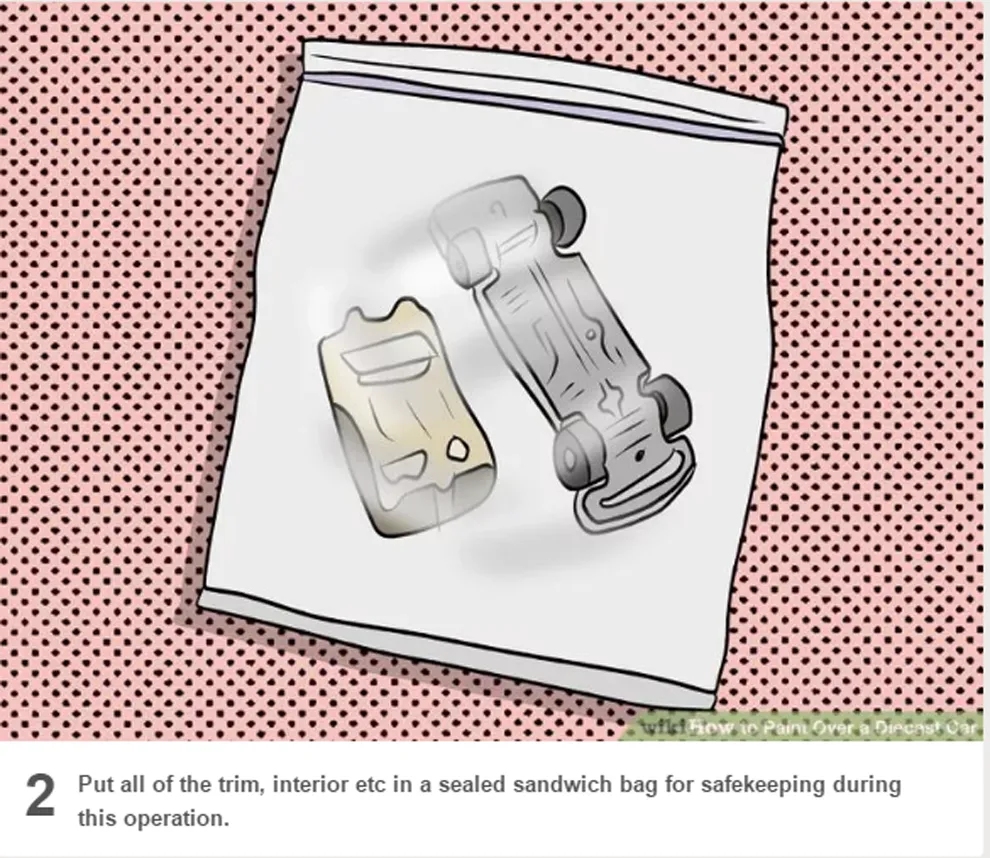

Before applying paint and detailing, the diecast car body needs careful preparation. This stage is critical for ensuring that the paint adheres properly and that your finished model looks its best. Start by disassembling the car as much as possible, removing wheels, windows, and interior parts. This gives you better access to all surfaces. The goal is to create a clean, smooth surface ready for painting. Any imperfections at this stage will show up in the final product, so don’t rush. Clean the car body with a mild detergent or a dedicated degreaser to remove any dirt, oil, or residue from manufacturing. Then, address any imperfections such as seam lines, flash, or scratches. Use a hobby knife or fine sandpaper to smooth these areas. After that, prime the car body with a suitable primer. This step helps the paint adhere to the metal and creates a uniform surface.

Cleaning and Surface Preparation

Thorough cleaning and surface preparation are the cornerstones of a successful diecast car project. Start by washing the car body with warm, soapy water, using a soft brush to gently scrub away any grime or residue. Rinse it thoroughly and let it dry completely. Inspect the surface for imperfections, such as mold lines, flash (excess plastic from the molding process), or scratches. Use a hobby knife to carefully trim away any flash. For deeper scratches, start with coarser sandpaper and gradually move to finer grades to smooth the surface. The goal is to achieve a perfectly smooth surface before priming. Clean the car body again after sanding to remove any dust or debris. The better the prep work, the better the paint job will look. Pay close attention to details to ensure a flawless finish.

Priming the Car Body

Priming is an essential step in making your diecast car. Primer creates a base for the paint to adhere to, improving durability and ensuring an even finish. Choose a primer specifically designed for model cars, as these are formulated to work well with the materials commonly used in diecast construction. Apply the primer in thin, even coats, allowing each coat to dry completely before applying the next. Several thin coats are better than one thick coat, as this helps prevent runs and drips. After the primer has dried, lightly sand the surface with very fine-grit sandpaper (such as 1000 grit or higher) to remove any imperfections and create an even smoother surface. Wipe away the sanding dust with a tack cloth or a soft, lint-free cloth. Once primed, the car body is ready for painting. Don’t skip the priming stage, as it is key to your project’s long-term success.

Painting Your Diecast Car

Painting is where your diecast car truly comes to life. Selecting the right paint and applying it carefully will transform your model into a stunning replica. Start by choosing paints specifically designed for model cars, which are available in various finishes like gloss, matte, and metallic. Acrylic paints are popular for their ease of use and low odor, while enamel paints offer durability. Spray paint is the preferred method for achieving a smooth, even finish, but you can also use a brush for detail work. Practice your painting technique on a test piece before applying paint to the car body. Apply the paint in thin, even coats, allowing each coat to dry completely before applying the next. This helps prevent runs and drips. Building up the color gradually ensures a better finish. Use masking tape to protect areas you don’t want to paint, such as windows or trim. After the paint has dried, you can apply a clear coat to protect the finish and add shine.

Choosing the Right Paint

The paint you choose will significantly impact the final look of your diecast car. The market offers several options. Acrylic paints are water-based and easy to clean, making them beginner-friendly. They dry quickly and have a low odor, but they may not be as durable as other options. Enamel paints, on the other hand, are oil-based and provide a durable, glossy finish. They take longer to dry and require mineral spirits for cleanup, but they offer excellent coverage. Consider your experience level and the desired finish when making your choice. Check the manufacturer’s recommendations for thinning and application techniques. Match colors as accurately as possible to the real car you are trying to replicate. Experiment with different brands and types of paint to find what works best for you. A good paint job is one of the most important aspects of a great diecast car.

Painting Techniques for a Smooth Finish

Achieving a smooth, professional finish requires careful painting techniques. Start by preparing your workspace, ensuring it is clean, well-ventilated, and free of dust. If using spray paint, hold the can about 6-8 inches away from the model and apply thin, even coats, overlapping each pass slightly. Avoid spraying too much paint at once, as this can lead to runs and drips. For brush painting, use a high-quality brush and apply thin coats, using even strokes in the same direction. Let each coat dry completely before applying the next. Use masking tape to protect areas you don’t want to paint, such as windows or trim. After the paint has dried, you can lightly sand any imperfections with fine-grit sandpaper and apply a clear coat to protect the finish. Practice these techniques to achieve the best results.

Adding Details and Decals

Adding details and decals is what takes your diecast car from a simple model to a highly detailed replica. This process involves applying decals, stickers, and additional details to enhance the car’s authenticity and visual appeal. Decals are often water-slide transfers that need to be cut out and applied with water. Position the decal carefully and use a soft cloth or cotton swab to remove any air bubbles. Stickers are self-adhesive and easier to apply, but be sure to align them accurately. Additional details may include chrome trim, badges, lights, and other small parts. These details can be added using super glue or model cement. A steady hand and patience are essential for this stage, as these small details bring the model to life. Consider this step the most rewarding aspect of the hobby.

Applying Decals and Stickers

Applying decals and stickers requires precision and patience. Water-slide decals are the most common type used on model cars. Cut each decal carefully from the sheet, close to the image, and submerge it in lukewarm water for a few seconds until it releases from the backing paper. Slide the decal onto the car surface and carefully position it with a soft cloth or cotton swab. Use the cloth to remove any air bubbles and excess water. For stickers, simply peel them from the backing and carefully apply them to the car surface, ensuring they are aligned correctly. Use a hobby knife to trim any excess edges. Once all decals and stickers are applied, you can apply a clear coat to seal them and protect them from damage. Take your time, and don’t rush the process to ensure a professional finish.

Adding Interior and Exterior Details

Adding interior and exterior details significantly enhances the realism of your diecast car. Interior details might include dashboards, seats, steering wheels, and gear sticks. These parts are often included in the kit or can be purchased separately. Exterior details can involve adding chrome trim, badges, lights, and other small components. Use a hobby knife and tweezers to carefully remove parts from the sprue, and assemble them according to the instructions. Super glue or model cement are used for attaching these details. Pay close attention to the placement of each detail to replicate the original car’s design. Adding these details is a rewarding process, as it brings the model to life. Take your time and enjoy the process.

Assembling Your Diecast Car

Assembling your diecast car is the final stage, where all the individual parts come together to form the finished model. This involves attaching the wheels, chassis, interior, windows, and any remaining details. Follow the instructions carefully. Start by attaching the wheels and chassis to the car body. Ensure the wheels rotate freely. Install the interior parts, such as the seats and dashboard, and then the windows. If necessary, use glue to secure the windows. Double-check that all parts are securely attached before moving on. Pay close attention to the alignment of all parts to achieve a neat and professional finish. A good assembly is just as important as the painting and detailing work. The result should be a complete, visually appealing, and well-built model.

Attaching Wheels and Chassis

Attaching the wheels and chassis is a key step in the assembly process. The chassis provides the base for the car and often includes the suspension and other mechanical details. The wheels must be securely attached so that they rotate freely. Make sure you have the correct wheels for your model. Align the chassis with the car body and attach it according to the instructions, using screws or glue. Next, insert the axles into the wheels and attach the wheels to the chassis. Ensure the wheels are aligned and rotate smoothly. If the wheels don’t rotate freely, check for any obstructions or misalignment. A well-assembled chassis and wheels are essential for a realistic and functional model.

Final Touches and Detailing

The final touches and detailing are essential for perfecting your diecast car. This stage involves any remaining detail work, such as adding weathering effects, applying a clear coat, and adding any final accessories. Weathering techniques, such as dry brushing and washes, can be used to add realism and give the model a used, worn look. Apply a clear coat to protect the paint and decals, and to give the model a glossy or matte finish. Add any final accessories, such as license plates, mirrors, and antennas. Inspect the entire model for any imperfections and make any necessary corrections. The final touches are what separates a good model from a great one. Pay attention to every detail and enjoy the satisfaction of completing your diecast car.